About Us

Compassion Appliances is one of India’s emerging names in plastic product manufacturing. Established in 2019 by Mr. Rajesh Garg, we began with a strong focus on air coolers and have since evolved into a full-scale OEM manufacturing partner for appliances and plastic components.

With a robust in-house infrastructure, state-of-the-art injection moulding technology, and a commitment to quality, we provide end-to-end plastic moulding solutions to brands across the country.

Infrastructure

We operate out of a 1,00,000 + sq. ft. facility, fully equipped with modern manufacturing lines, skilled manpower, and integrated systems to support the entire production lifecycle.

Our in-house capabilities include:

- High-tonnage Injection Moulding (150 tons)

- Component Assembly & Testing

- Dedicated Quality Inspection Zones

- On-site Warehousing & Packaging

- Ready-to-dispatch Logistics Support

This gives us an edge in ensuring speed, precision, and scale — all under one roof.

Machinery

We are equipped with over X+ injection moulding machines ranging in capacity from 150 tons, capable of producing small intricate parts as well as large structural components.

Our machines are regularly maintained, calibrated, and operated by highly trained technicians to ensure high productivity and consistency in every cycle.

Vision

To become the go-to manufacturing hub for plastic components and a preferred OEM partner known for quality, transparency, and reliability.

We proudly serve clients in Air Coolers & Cooling Appliances, Geysers & Home Heating Equipment, Juicer Mixer Grinders & Kitchen Appliances, Custom Plastic Moulding for OEMs

Our Workforce

In-House Facilities

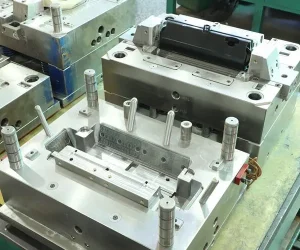

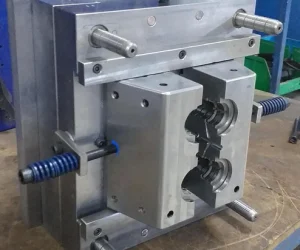

Insert Manufacturing

Machining

Reverse Engineering

Mould Manufacturing

Metal To Plastic Conversion

Rubber Compression Moulding

Transparent Polycarbonate Moulding

Assembly

Plastic Injection Moulding

Overmoulding & Insert Moulding

Mould Designing

Our Journey

2019Company founded by Mr. Rajesh Garg with air cooler manufacturing

2020 First OEM orders fulfilled with full in-house assembly

2021 Expanded into geysers & kitchen appliance segments

2023 Upgraded facility to 2,00,000+ sq. ft. and added high-capacity moulding machines

2024 Became a full-stack OEM solution provider with warehousing and dispatch integration

2025 Expanded into a complete OEM solutions provider with integrated warehousing and dispatch

Our Journey

2019-Company founded by Mr. Rajesh Garg with air cooler manufacturing

2020-First OEM orders fulfilled with full in-house assembly

2021-Expanded into geysers & kitchen appliance segments

2023-Upgraded facility to 2,00,000+ sq. ft. and added high-capacity moulding machines

2024-Became a full-stack OEM solution provider with warehousing and dispatch integration

2025 – Expanded into a complete OEM solutions provider with integrated warehousing and dispatch

Our Team

Our leadership and factory teams work hand-in-hand to ensure every order meets expectations.

Rajesh Garg

( Founder & Managing Director )

A visionary with over a decade of experience in plastic manufacturing and business development.

Vishal Garg

( Production Head )

Overseeing day-to-day operations and quality assurance

Nitin Singh

( Tooling & Design Team )

Collaborates with OEMs for mould and product development

Mayra Bansal

( Quality Control Manager )

Ensures every batch adheres to stringent inspection protocols

Trusted By Brands Like